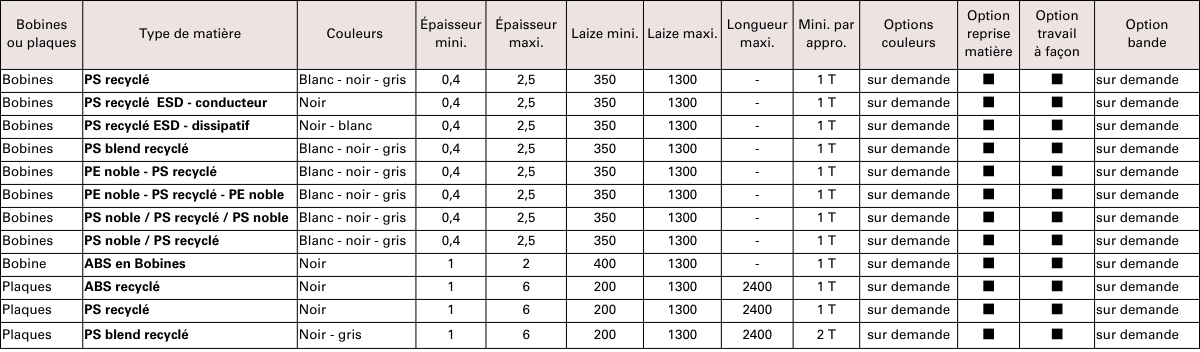

Produits

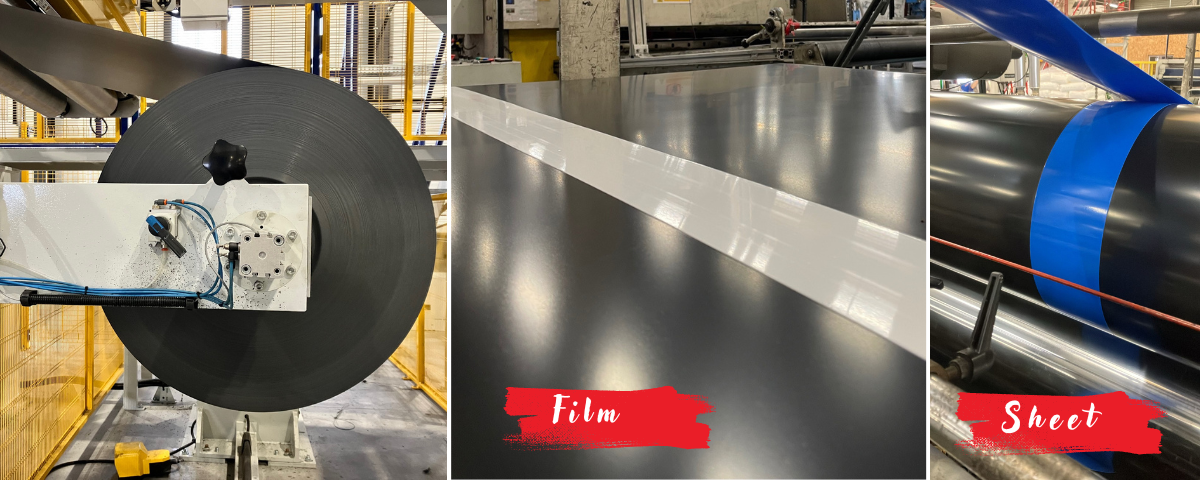

All our products [Film and Sheets], resulting from extrusion, are made of polymers [PS, PE, PP, ABS] which have in common that they belong to the thermoplastic family and are highly recyclable.

Our main materials are:

- Recycled PS

- PS ESD

- Recycled ABS

- PSPE

- PEPSPE

- PP

rHIPS (recycling high impact polystyrene)

Polystyrene is a hard and brittle plastic. It exists in two subfamilies, opaque shock PS and more resistant to shocks than crystal PS which is transparent. It is one of the most common plastics used in our production. VICAT melting point: 180-220°C

rABS (recycling Acrylnitril Butadien Styrol)

ABS is an industrial thermoplastic polymer combining 3 different monomers (Acrylonitrile, Butadiene, Styrene) whose most important properties are resistance to impact and mechanical issue. In addition, for more demanding applications, there are grades of ABS with high impact resistance as well as others with high flame resistance. VICAT melting point: 192-240°C

rHIPS ESD (ElectroStatic Dissipation)

ESD products are electrically conductive or dissipative plastics that have surface and volume specific resistance and thus avoid electrostatic charges. ESD plastics dissipate static electricity to protect components that may be susceptible to electrical shock.

PE (Polyethylene)

Polyethylene refers to ethylene polymers, it constitutes the most common plastic material. Its name comes from the fact that it is obtained by polymerization of ethylene monomer. HDPE plastic is opaque, impact resistant, impervious to water, certain chemicals, gas and aromas. Not to be confused with LDPE, low density polyethylene. Melting point: 120-140°C

PP (Polypropylene)

Polypropylene is often chosen because of its low weight and exceptional impact resistance. Melting point: 160°C

The main colors used are black / white / blue / grey but we are able to respond to all other desired colors.

ALGOPLAST has specifically developed the production resources to offer its thermoforming customers 100% recycled products, with a very advantageous quality-price ratio.

Listening to the needs of its customers, and having a strong sensitivity to innovation, ALGOPLAST also offers specific products, adapted to packaging applications for industrial or cosmetic products:

- coextruded products with anti-scratch quality,

- dissipative products (for electronic components),

- recycled products with colored bands,

- special products intended for targeted applications such as shaping foams, neutralizing humidity in the air (VCI treatment).

We offer a full range of services from the extrusion of customer scraps to recycling, through engineering, consulting and training.